Insights

Product Development Engineers Enhance Testing Capabilities with Remote Monitoring and Control with TestEquity’s Thermal Chamber

In a strategic move to enhance our testing capabilities and expand our service offerings, Prodigy’s product development team invested in a new TestEquity thermal chamber at the beginning of the year. This acquisition aligns with our ongoing efforts to internalize pre-compliance testing services we currently provide to our valued customers.

Our team was eager to capitalize on the chamber’s advanced features, and within a short period, we successfully utilized it to investigate a specific product concern raised by one of our clients. The chamber’s capabilities quickly piqued the interest of our management team, who recognized its potential to streamline our testing processes and enhance our overall efficiency.

Our product engineers were particularly impressed with the chamber’s remote monitoring capabilities. The ability to oversee the chamber’s operation from our desks proved to be an invaluable asset, saving us time and effort. Capitalizing on the chamber’s ethernet connectivity, our engineers promptly developed a method to track its performance across our internal network. Additionally, they seamlessly implemented a web-based solution that grants limited access to the chamber’s data from anywhere with an internet connection. This web-based solution has proven to be a valuable tool for our team, enabling us to monitor the chamber’s performance remotely and make informed decisions accordingly.

The implementation of remote monitoring capabilities for the thermal chamber extends beyond mere technical ingenuity; it offers several tangible benefits. Primarily, it eliminates the need for physical presence to monitor results and respond to events, a significant advantage when the equipment is in an inaccessible location or distant from the workplace. Real-time data acquisition, coupled with alarm functionality, facilitates timely responses to critical events. Remote access also enables seamless data storage, retrieval, and transfer. Advanced remote-control capabilities extend to correcting issues, modifying profiles, and initiating or halting processes remotely.

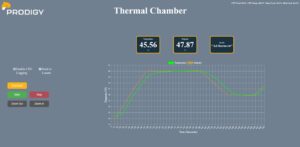

The web server’s control over the chamber is limited by the functionality exposed by the chamber’s SCPI or Modbus communication protocols and the server’s implementation. Additional functionalities are readily achievable. Prodigy’s server enables temperature unit conversion to Celsius, real-time temperature readings, and access to current setpoints and active profiles. It also records and stores the results of the last ten activated profiles. The server can start, stop, and pause existing profiles, or utilize manual setpoint and ramp time adjustments to conduct automated testing directly from the server.

The server can log data to a CSV file locally and allow users to download it directly from the web browser. Usage statistics can be stored in a database, displayed on a web dashboard, or downloaded.

Remote communication is beneficial, but its effectiveness hinges on a user-friendly interface. Prodigy’s product development engineers developed a Graphical User Interface (GUI) that makes chamber access and control intuitive and robust. The GUI provides a visual representation of chamber performance and status, enabling easy data retrieval, parameter and profile changes, and process initiation or termination through point-and-click interactions. Chamber data can be evaluated, with warnings and alerts triggered under specific conditions. By automating the interface and providing a defined access method, a repeatable and reliable process is established. This reliability and ease of use can extend to other access methods, enabling expansion from local networks to web-based access.

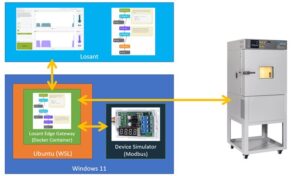

For efficient thermal chamber testing, product development engineers can utilize a web server hosted on a device capable of TCP socket communication, such as a PC, SoC, or microcontroller. The server size should match the workload. A microcontroller managing multiple chambers and clients may be inadequate, while a high-end server for a single chamber and limited clients might be too costly.

Prodigy opted for a quick, locally hosted solution. A Raspberry Pi 4B served as the web server and chamber interface, using Python for the backend and HTML/CSS/JavaScript for the frontend. Gunicorn and Uvicorn hosted the server. This server-based interface allows unlimited users to view chamber data without additional software. Users simply need to connect to the server’s network and enter the IP address and port in their web browser.

Local hosting eliminates the need for additional security measures as the server is not exposed to the internet. Expanding accessibility beyond the local network requires implementing security features. A cloud-based solution simplifies this process by pushing data to the cloud, enabling access from anywhere without exposing the server directly. Prodigy’s Losant IoT Platform seamlessly integrates with the server, pushing setpoint and temperature data in real-time. This additional feature was implemented and tested within hours.