Insights

Validating Analytical Models: Prodigy’s reliable testing equipment and expertise

When it comes to validating analytical models against reality, relying solely on computer-aided design software has its limitations. While it provides valuable insights, in Product Development, physical testing is crucial to ensure a successful design. However, the process of planning, developing, executing, iterating, and documenting these tests can be costly and time-consuming, especially if inexperienced engineers and inadequate equipment are involved. At Prodigy, we take pride in our commitment to delivering high-quality testing and documentation to our customers. In this article, we will delve into the exceptional product design testing capabilities offered by Prodigy.

- Universal Force Tester

To effectively support in-house material testing, Prodigy invested in a universal force tester. The motorized tension / compression test stand allows for highly configurable single-column tests including but not limited to:

- Break Testing

- Cycling

- Limit Testing to a load or distance

- Load holding

- Elongation Testing

- Tensile Testing

- Compression Testing

- Peel Testing

- Shear Testing

- Thermal Chamber

With many clients requiring thermal cycling conditioning of components, Prodigy’s New Product Development team met this continuous need by obtaining a thermal chamber. The Watlow F4T Controller allows for customizable temperature profiles to be implemented, allowing Prodigy to meet the specific cycling or evaluation needs of our clients. See below for further chamber specifications:

- Temperature Range: -73°C to 175°C

- Internal Volume: 16” W x 12” H x 14” D

- 3” Access ports on either side of the chamber

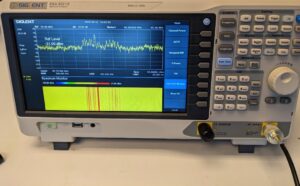

- Spectrum Analyzer

With increasing regulatory requirements of electronics and the increasing need for wireless communication, Prodigy has invested in a Spectrum Analyzer and accessories that allow our engineering staff to validate functionality and performance of a wide range of applications. Some applications include checking for EMI issues, validating antenna operation, and verifying wireless communications.

- PCB Bring-Up Equipment

Designing and performing a board bring-up for PCBs is a common task handled by Prodigy’s electrical engineering department. Whether it’s impedance / continuity testing or evaluating thermal hot spots, the following equipment is readily available for these evaluations and assessments:

- Digital Multimeters

- Logic Analyzers

- Bench-top FLIR Thermal Camera

- Oscilloscopes

- Power Supplies

- Soldering Irons

- Solder Reflow Oven

- Additional Electrical Equipment

In addition to the equipment conveyed in “PCB Bring-Up Equipment”, Prodigy has invested in the following equipment to support a variety of electrical evaluations:

- Withstand Voltage (HIPOT) Tester

- Synthesized In-Circuit LCR / ESR Meter

- TDS / Conductivity Meter

- Arbitrary Waveform Function Generator

- Optical & Thermal Equipment

To support opto-mechanical and opto-electrical project needs, the following equipment has been added to Prodigy’s tool inventory:

- Light Meter

- Laser Power & Energy Meter

- Microscopes

- Vane Thermo-Anemometer

- Handheld FLIR Camera

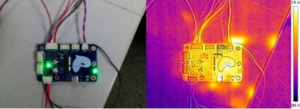

(Images from the FLIR Camera)

- Metrology & inspection equipment

To successfully perform incoming part inspections and efficiently verify critical tolerances & fits, Prodigy has accumulated the following metrology equipment:

- Surface Roughness Tester

- Coating Thickness Gauge

- Micrometers

- Digital Calipers

- Height Gauges

- Dial Indicators

- Pin Gauges

- Gauge Blocks

- Thread Gauges (SAE & Metric)

- Torque Screwdrivers & Wrenches

- Hydrometer

Transitioning from prototype design to physical testing can be overwhelming, requiring significant investments in equipment and operator training. Thankfully, Prodigy’s innovative product development specializes in guiding clients from diverse industries through the entire process seamlessly. By leveraging our expertise, we have successfully integrated various instruments, incorporating automated controls to execute complex testing scenarios tailored to specific client requirements. Should your project demand additional equipment, we are committed to investing in the necessary resources.