Our Work

Embedded Product Line Development for Harmar

Challenge

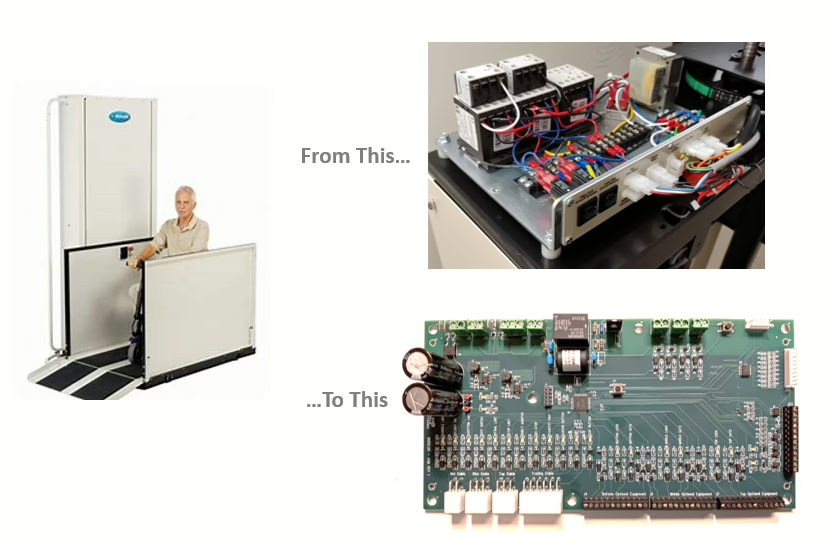

Harmar engaged ITE (Prodigy) to modernize the embedded control system for its Highlander lift product line. The project required integrating complex features—such as data logging, fault handling, and thermal monitoring—into a compact and reliable electronics platform. The effort was complicated by tight timelines, constraints posed by legacy components, and evolving firmware requirements. Harmar sought a development partner capable of rapid prototyping and delivery of production-ready hardware and software through a structured, iterative process.

Solution

ITE applied a phase-gated development approach, initiating the effort with a breadboard prototype to validate system-level requirements. Using Harmar’s CAD models and components, ITE implemented and refined critical firmware features, including performance monitoring, timestamped data logging, and flood state detection. The project advanced to schematic development and PCB layout, culminating in the fabrication and delivery of five production-quality prototype boards. Weekly design reviews via Microsoft Teams and cloud-based collaboration through Box.com ensured alignment, transparency, and agile responsiveness throughout.

Outcome

The project delivered a robust embedded system that met Harmar’s performance, reliability, and manufacturability goals. The new hardware and firmware architecture enabled enhanced diagnostics and simplified future iteration. Delivered on budget across all phases, the solution positioned Harmar to move confidently into production. The partnership with ITE allowed Harmar to minimize development risk, shorten time-to-market, and retain full ownership of the design and all associated intellectual property.