Our Work

Enhancing Connectivity and Scalability: Ranpak’s IoT Prototype for Global Packaging Machines

Challenge

Ranpak faced a significant challenge in enhancing the connectivity of their packaging machines, which are distributed globally across various distribution centers, 3PL facilities, and end-user sites. With approximately 100,000 machines in use, the goal was to enable remote connectivity for a subset of these machines to facilitate data transmission for operational analysis and customer service improvement. The challenge was to achieve this at an economical cost point while ensuring the solution could be scaled in the future.

Solution

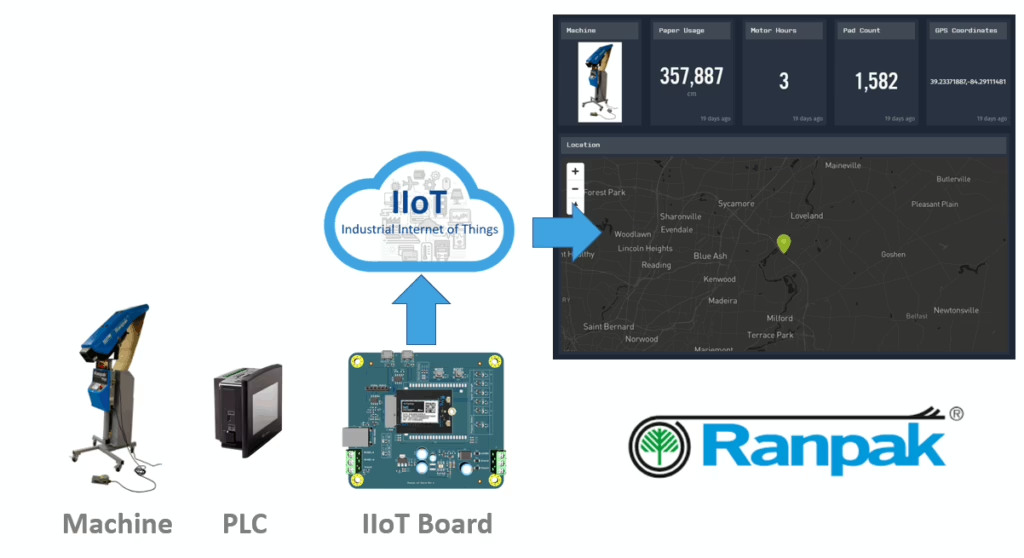

To address this challenge, Ranpak partnered with ITE (Prodigy) to develop a prototype for enabling IoT connectivity of their packaging machines. The project followed a structured phase-gate approach, starting with the development of product and system requirements, hardware selection, software development, and the creation of a demo dashboard. Key activities included project planning, risk registry development, system architecture design, and ongoing collaboration with Ranpak through regular meetings and content sharing.

Outcome

The successful implementation of the IoT connectivity prototype resulted in several key deliverables, including updated product requirements, a risk registry, system architecture, firmware, a web-based dashboard, and a breadboard prototype. The project was completed within the estimated eight-week timeline and within the budget of approximately $48,719 for labor and $1,155 for materials and travel. This initiative not only enhanced Ranpak’s ability to remotely monitor and analyze their machines but also laid the groundwork for future scalability and improvements in customer service.